How Technical Data Packages Support Digital Thread Initiatives

By: Scott Collins

The goal of business transformation for manufacturing companies is not about winning a technology acquisition race, but rather improving the flow of essential information. In that regard, a technology with a rather plain name — Technical Data Package — is making a big impact as companies sort through how best to connect all stakeholders with essential product data.

The basic definition of Technical Data Package (TDP) is a set of electronic content created by product development that describes a product or item. The TDP carries all the information needed by downstream teams in the supply chain. The original data include all the familiar pieces of product development, such as bills of material (BOMs) with approved manufacturers/vendors lists (AML/AVLs), 3D CAD models, drawings and schematics, standards documents, supplier instructions, quality inspection information, and other requirements-oriented data.

Incorporating TDPs is a good step toward breaking down those legendary metaphoric silos which inhibit effective collaboration. Information is gathered directly from the people who created it and the systems which hold it. A TDP then makes the data available to the rest of the organization, in an easy-to-use format. Each role player gets only the information they need.

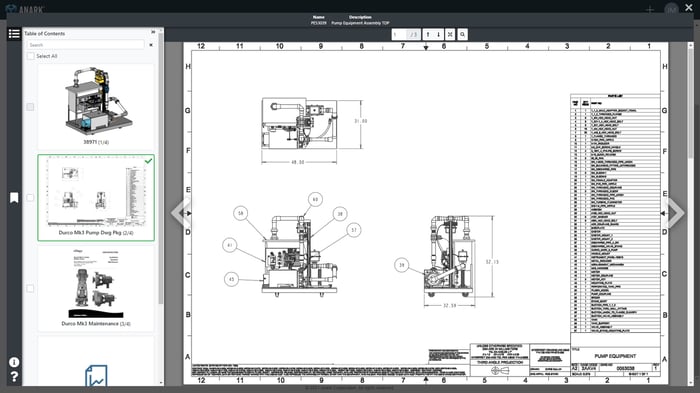

Figure 1 - Sample Anark Web Based TDP with 3D MBD CAD, Legacy 2D Drawings, Documents and BOM

Integrating Technical Data Packages into existing workflows is easier than other digital initiatives. The typical user of a TDP doesn’t have access to a PLM or ERP system and wouldn’t know how to use the software if they did have access. Instead, a TDP should allow access to data without having to learn complex tools.

TDPs don’t have to give away the crown jewels. They can carry any kind of engineering information, and they can be assembled to present to each user only the specific information they need to do their work. This protects intellectual property in a way that many tools cannot.

In Search of the Perfect BOM

A research project with the auspicious title of “In Search of the Perfect BOM” notes one huge bottleneck when transferring information to Electronics Manufacturing Service (EMS) providers. EMS providers traditionally use “parsers” to convert data into neutral data formats common in the electronics manufacturing industry. Each data format the EMS team received requires a separate parser and a specific script for successful conversion. The research team found one EMS provider maintains an internal organization of more than 80 people whose only function is to interpret customer data and translate it for use in their production systems.

Every time there is manual manipulation of data, errors occur. One EMS reports seven out of ten customer data transmissions routinely need multiple levels of clarification. Another reports that up to 20% of data refer to obsolete products, requiring more time for clarification and updating. “[The] ability to start up new products rapidly is impacted by the quality of our documentation,” another manufacturer reported. “Thirty-five percent of the component data have problems.”

Redistributing data from multiple sources to multiple recipients

TDP recipients are information consumers; their needs are very specific to their roles. Imagine a nutritional counselor recommending the same large buffet to each client, when one only needs dark leafy greens and another only protein. TDPs are the manufacturing equivalent of an efficient nutritional counselor, distributing data in a targeted, easy-to-digest form.

Data is as important once the product is sold as to when it is being manufactured. A study of defense systems by NIST says more than 70% of lifecycle system costs are incurred during maintenance, support, and retrofit. This same study reports a documented time savings of 25 to 1 when TDPs are used as part of a larger model-based workflow. The NIST report notes: “Companies are beginning to realize that integrating the various models with collaborating applications that assist the various functions throughout the enterprise can provide untold benefits not only to the enterprise but to all downstream customers. This includes those needing a TDP to enable provisioning, provide logistics, and sustain the real product.”

When a Technical Data Package becomes Digital Thread value

Assembling TDPs to organize and share manufacturing information is the first step, but just as important is to share this information within a secure, digitally connected content collaboration environment that requires no training; this is how a TDP becomes a major contributor to Digital Thread value. In such an environment, all participants from engineering, sales, supply chain, sourcing, manufacturing, contract manufacturing, and service can access, mark-up, and collaborate with TDP content and one another in traceable, closed loops from any device, with no complex software tools required. Easy-to-use, traceable collaboration improves understanding—driving down bid inflation with improved supply chain management, minimizing scrap and rework in manufacturing while reducing overall delivery risk, and optimizing field service communications and operations.