Digital Work Instructions and effective collaboration have long been known to offer advantages to manufacturers, but how do you get started?

In a manufacturing workflow, only the latest information is useful. If an Engineering Change Order comes down, but the update doesn’t ripple through the ecosystem, to both suppliers, and fabricators, there will be trouble.

Communications are too often blocked by manual creation and transmission of work instructions. If engineering makes a change that affects part manufacturing or assembly, the process stops while the update takes place. And that’s assuming the information is being communicated clearly, accurately, and in a timely fashion. The best way to eliminate this bottleneck is with digital work instructions.

Many companies have digitalized processes, but they rely on complex products used only by specific engineers. Most downstream workers don’t have access to these products because of their cost and complexity. Even if they did have access, the cost of training and staying up-to-date with these products is an expense management would rather avoid.

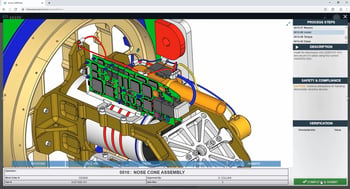

There is a clear need for digital work instructions crafted in a smart digital environment, yet able to clearly communicate work instructions to those who do not use CAD and PLM in their daily routine. When something changes, the digital platform needs to automatically make the change, and do so in the visual and task-specific language of those who need the information.

Such a smooth workflow for information starts with the use of model-based engineering (MBE). The model holds not only geometry but also Product Manufacturing Information (PMI), Geometric Dimensioning and Tolerancing (GD&T), and automates the creation and updating of the various “bills of materials” required (BOM, mBOM, eBOM, service BOM, etc).

Data for a digital workflow needs to present the right information from the model in both graphic and text. Information needs to flow two ways. If there is a question, can it be answered within this digital thread of intelligent manufacturing data, or must employees bypass the technology? Digital work instructions are perhaps the most obvious example of the need for clear collaboration, unimpeded by outdated processes or cultural challenges (“that’s not the way we do it here.”)

Collaboration at Cohu

Cohu manufactures products for the semiconductor industry. It is a demanding field; their products are changing constantly to reflect industry innovation. Anark Core provides them with a modern, intelligent digital manufacturing communications platform. “When I joined as CIO, we needed to simplify our landscape, streamline our business processes, and integrate our tools so we could focus on innovation,” says Craig Halterman, Coho Chief Information Officer.

Halterman says he inherited a mishmash of legacy systems, “dated and highly customized” (which usually means ‘expensive to maintain’). Much of the workflow was manual, as employees moved data from one system to another.

Cohu often acquires small new companies in its field but was getting frustrated by not being able to integrate the new teams into the workflow. “We needed to modernize our backend processes and our manufacturing processes,” says Halterman. There were also collaboration issues with subcontractors and others in the manufacturing and supply chains. “Supplier visibility and collaboration are key to our success. Having information come from our supply chain is significant."

Halterman says the use of Anark Core and Oracle Cloud allows Cohu to “connect our integrated digital thread environment to our people, including our supply chain.”

Cohu found an unexpected benefit in moving to intelligent workflow — increased protection for intellectual property. “In the era of cybersecurity risks, it is critical to secure intellectual property and protect value.” Installing the digital workflow means “cybersecurity is no longer a disablement of the business. Rather, information management and intellectual property protection are continued throughout the lifecycle.”

For those who realize it is time to do what Cohu has done to create an intelligent, collaborative framework for digital work instructions, Halterman says the focus has to be bigger than the software solutions. “It is not enough to only focus on the technology and the system. We had to make sure the people and the processes were an integral part of our solution.” Part of that process was overcoming cultural resistance. Another part was the use of Anark Core’s ability to package up the correct data from model-based engineering and deliver it to the manufacturing and supply groups in understandable visual and textual forms.

To learn more, please read our blog from June 30, “How Technical Data Packages Support Digital Threads.”