The Goal

Have you ever heard the phrase “meet them where they are”? Sure, you have! But have you ever heard of a collaboration platform that successfully does it for everyone across your organization? Most manufacturers have not.

This was the problem Anark set out to solve for manufacturers by developing Anark Collaborate, a modern content collaboration platform designed for manufacturers that combines file-sharing app convenience and communication app simplicity with a deep understanding of technical product data.

The Theory

To do this, Anark needed to know the facts direct from manufacturers to validate that this was a problem worth solving. After all, PLM vendors have developed extensions to improve technical data sharing with non-engineering teams, while ERP and SCM vendors are doing the same in their applications. But none of these approaches meet the diverse manufacturing workforce and their suppliers where they are. In fact, they did the opposite, forcing compromises on the people that need the data the most. Meanwhile, the use of generic content collaboration, file sharing, and email spirals out of control as these tools meet people where they are, but remain disconnected from systems of record, and don’t support the technical data and processes that manufacturers need to operate.

Lifecycle Insights conducted research with 200 manufacturers to understand the state of technical content collaboration. Their work revealed the extent of the problem for manufacturers, the key capabilities required to solve the problem, and the value that could be gained by solving the problem.

The Problem Revealed

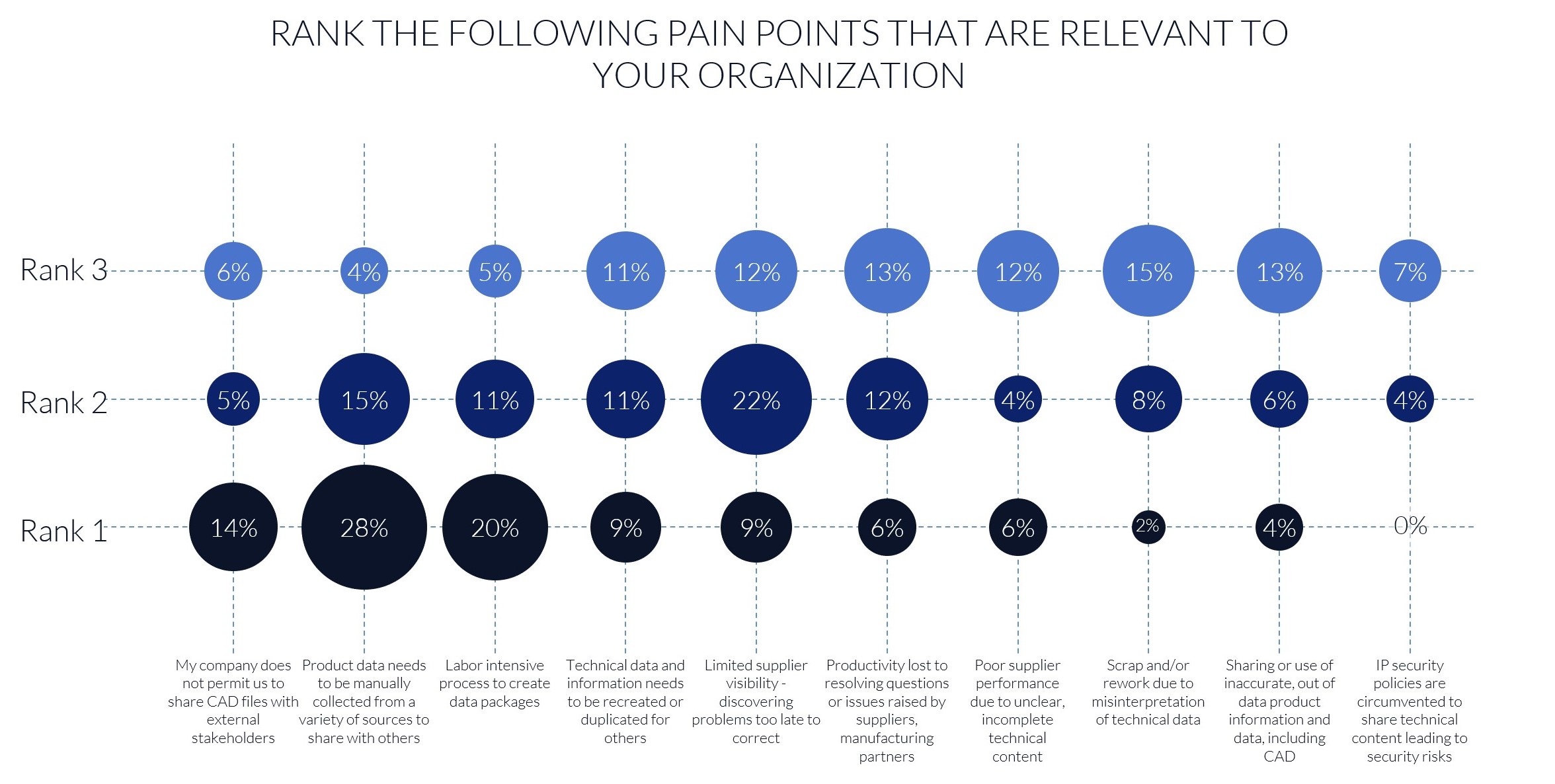

Figure 1: Ranking of Top Collaboration Pain Points for Manufacturers.

Source: Lifecycle Insights Research – The State of Technical Content Collaboration. n=201

The research uncovered the biggest problems by asking manufacturers to rank their organizational pain points, Figure 1. The top ranked problems were:

- Product data needs to be manually collected from a variety of sources to share with others.

- Limited supplier visibility – information needs to be recreated or duplicated for others.

- A labor-intensive process to create data packages for sharing data with others.

Additionally, it was reported that scrap and rework result from misinterpretation of technical data, poor supplier performance results from unclear incomplete content, and productivity is lost to resolving questions from suppliers and other manufacturing partners.

The Complete Results

With the complete 30-page research report, Anark had the facts direct from manufacturers to validate that this was a problem worth solving. In addition to the data shown in Figure 1 above, the research provided detailed insight across:

- Company and respondent demographics

- Business processes and challenges

- Internal and External collaboration and product data sharing tools and techniques

- Desired technical content collaboration capabilities

- IP security considerations

Anark used this detailed research to strengthen product and go-to-market strategy as it prepared to launch Anark Collaborate, the world’s only content collaboration platform designed for manufacturers.

Get the Full Lifecycle Insights Research Report

If you’re interested in the full 30-page report from Lifecycle Insights, please fill out the form below.