External Collaboration

Optimized collaboration with customers, suppliers, and external agencies

Improve cycle times, customer visibility, and supplier collaboration with secure, universal access to digital product definition. Anark simplifies model-based publishing and collaboration so your teams can focus on speed, quality, and innovation.

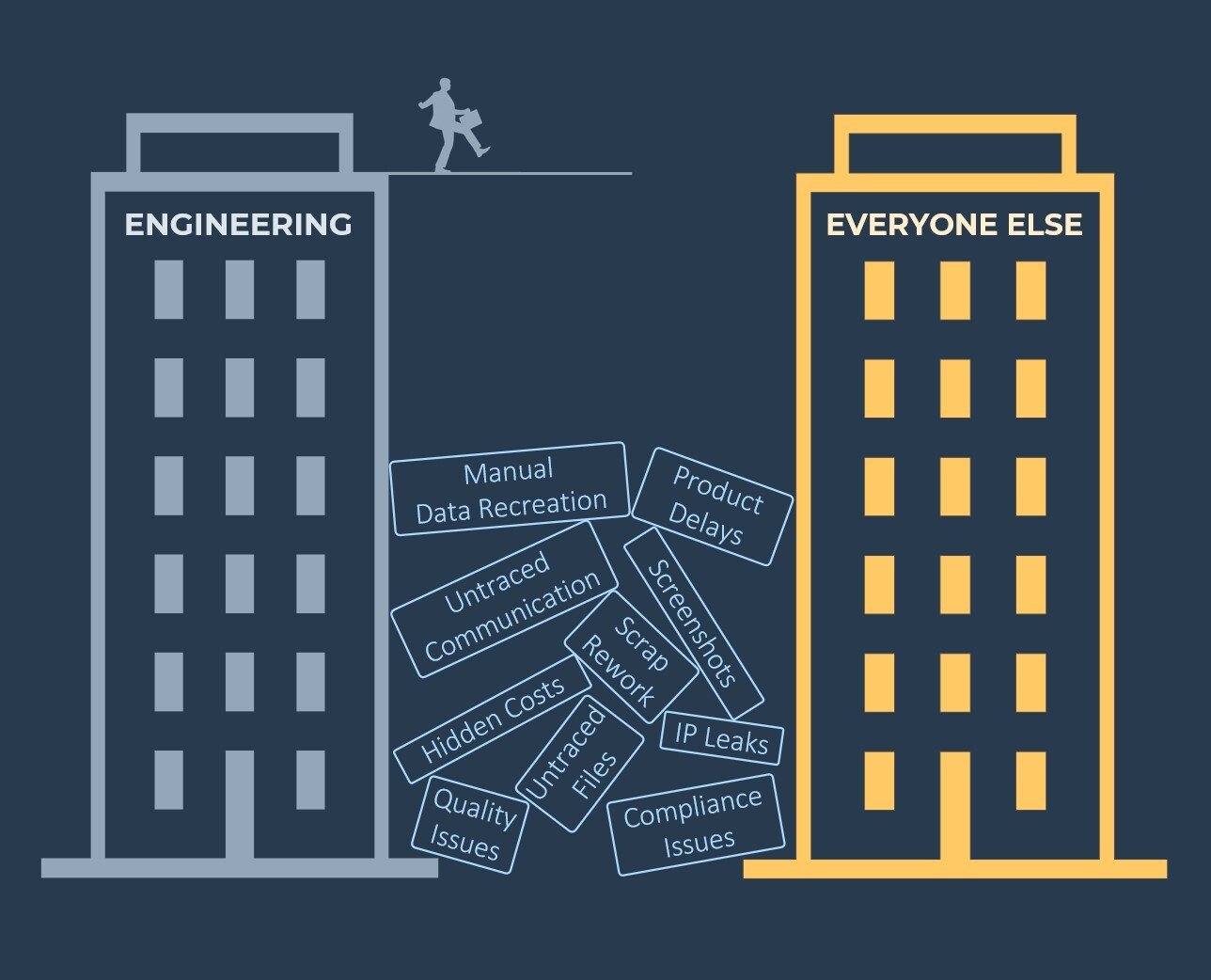

Your existing platforms promised a closed-loop digital thread to support the model-based enterprise (MBE), but they continually fall short. Complex 3D models and data management systems leave critical gaps in your workflows that lead to delays, scrap, and quality issues.

Anark changes that.

Whether you're starting with 3D models or advancing to MBE level 6, Anark delivers engineering data to everyone across your digital engineering and manufacturing processes.

Anark software connects to your existing tools and delivers powerful digital product definition data in easy-to-use technical data packages (TDP), 3D PDFs, and model-based collaboration spaces.

Empower internal and external teams with a traceable digital thread of 3D models, 2D drawings, BOMs, work instructions and more without CAD and PLM complexity.

Automate model-based publishing to scale collaboration, improve traceability and maximize efficiency across the enterprise.

Global leaders like GE, Boeing, and Lockheed Martin use Anark to transform their product collaboration with measurable results.

reduction of supplier interaction time by automating TDP publishing during early supplier collaboration.

of engineering time freed up from finding, packaging, sharing, and explaining data with email and disconnected documents.

reduction of engineering errors by collaborating in the context of shared technical data.

TDPs published per year by automating PLM-integrated TDP publishing.

Anark automatically applies CUI markings, smart watermarks, and IP labels to 3D CAD, TDPs, and work instructions. Ensure compliance, control access, and enable secure collaboration across suppliers, customers, and the extended enterprise.

Transform 3D CAD into universally accessible, model-based content that empowers teams, suppliers, and customers to collaborate, build, and deliver with confidence. Configurable publishing recipes and templates simplify the creation of high-quality Technical Data Packages (TDPs) tailored to your needs.

✔️ Simple 3D CAD publishing for rapid collaboration

✔️ Advanced MBD and PMI translation

✔️ Compliant Technical Data Packages (TDPs)

✔️ 3D PDF and 3D HTML publishing

Harness the full power of your CAD data—without PLM complexity.

We’ve focused on solving complex challenges so you can focus on innovation. Click each topic below to learn more.

Optimized collaboration with customers, suppliers, and external agencies

Bridge collaboration gaps to extend the digital thread to everyone who needs it

Harness the full power of model-based definition across the enterprise

CUI, FAA Type Certification, MIL-STD-31000B, DoDI 5000.97, DoDI 5200.48, Audit Trails, and more

Still need a 2D print? No problem, and we will help you close the feedback loop and build a digital thread.

Publish high quality engineering product data from CAD, PLM and other manufacturing systems

Modern microservices and API-first architecture extends value to existing systems and tailors experiences for a diverse set of applications

Flexible IP security with role-based access controls (RBAC), identity management integration, dynamic watermarking, and full traceability

Publishing and workflow synchronization with authoritative sources

"I really love my job, getting people to use model-based solutions from Anark and seeing their eyes light up when they get it. It's astounding. It's just a great feeling.

Model-based, to me, is an exciting journey that transforms our manual, document based business processes into a digital thread. The result is faster delivery, better quality, and a more collaborative environment that breaks down silos."

"The move to 3D is already delivering ROI—speeding our ability to meet FAA requirements while driving additional savings in production and quality inspection use cases.

We’re about 75% automated today and we are working toward 95%. This will save our engineers anywhere from 15 minutes to 5 hours of work per part. So, automation is another big win for us."

Configuration Management Engineer

Real-time collaboration (in Anark) rather than email allows us to track communication and resolve (supplier) issues a lot faster than before. And our sourcing and procurement team can visually verify the parts they are ordering without help from Engineering.

![]()

“We’re setting a higher bar with 3D TDPs from Anark. One that moves us forward with a scalable, future-ready approach, rather than falling back to 2D drawings and later struggling to rebuild momentum around 3D.

We’re super appreciative of the work Anark has done with us, and their engagement with us at every level has been wonderful. The help Anark provided our team allowed us to continue to move at the pace of a startup.”

Rick Florence

Configuration Manager – Aircraft Certification

"Anark is empowering over 900 students each semester to engage with complex engineering data in a clear, accessible, and modern way. They’re using PDM systems, NX, Teamcenter, and Anark Collaborate from day one. I introduce them to these tools not by talking about them, but by using them—just like in industry."

Assistant Professor in the School of Engineering

“We needed a technical data collaboration hub because we struggled to seamlessly exchange diverse technical data types, which resulted in collaborative processes that were still largely untraced. Anark Collaborate is a central component of our digital engineering environment that delivers the model-based collaboration and full traceability we need. IP security is of the utmost importance to us.”

"You know that 4 parts I did yesterday? Well I did 40 parts in an hour this morning! Because I can look at the monitor and have everything right there instead of running back to my workbench to look at the drawing and try to remember the numbers."

Discover manufacturing industry insights, news, product videos and more from the people redefining digital collaboration.

See how we connect everyone to the technical data and expertise they need.

Copyright 2024 Anark Corporation | 4775 Walnut Street, Suite 200, Boulder, CO 80301